A faster, cleaner way to install brick slips

Britain’s construction industry is changing:

With the demand to deliver hundreds of thousands of new homes every year, traditional bricklaying alone can no longer meet the speed, cost and labour requirements of modern development. Rising material costs, a shortage of skilled bricklayers and slow, weather-dependent programmes have driven a major shift toward: Reduced carbon Modern Methods of Construction (MMC), timber frame and panelised building systems. Brick Slip Systems have the answers:

Manufacturing at Scale

Brick Slip Systems is a Midlands based SME that provides a reliable, UK-manufactured façade solution — helping contractors build faster, safer and more cost-effectively.

With an output capacity of 4,000+ tracker boards per month, we are equipped to support:

- Consistent, volume demand supply chains.

- Multi substrate and MMC projects.

- Large-scale residential and commercial. developments.

- Mass production of Fibre cement and EPS board systems: sizes 1200mm x 2400mm (*bespoke sizes available).

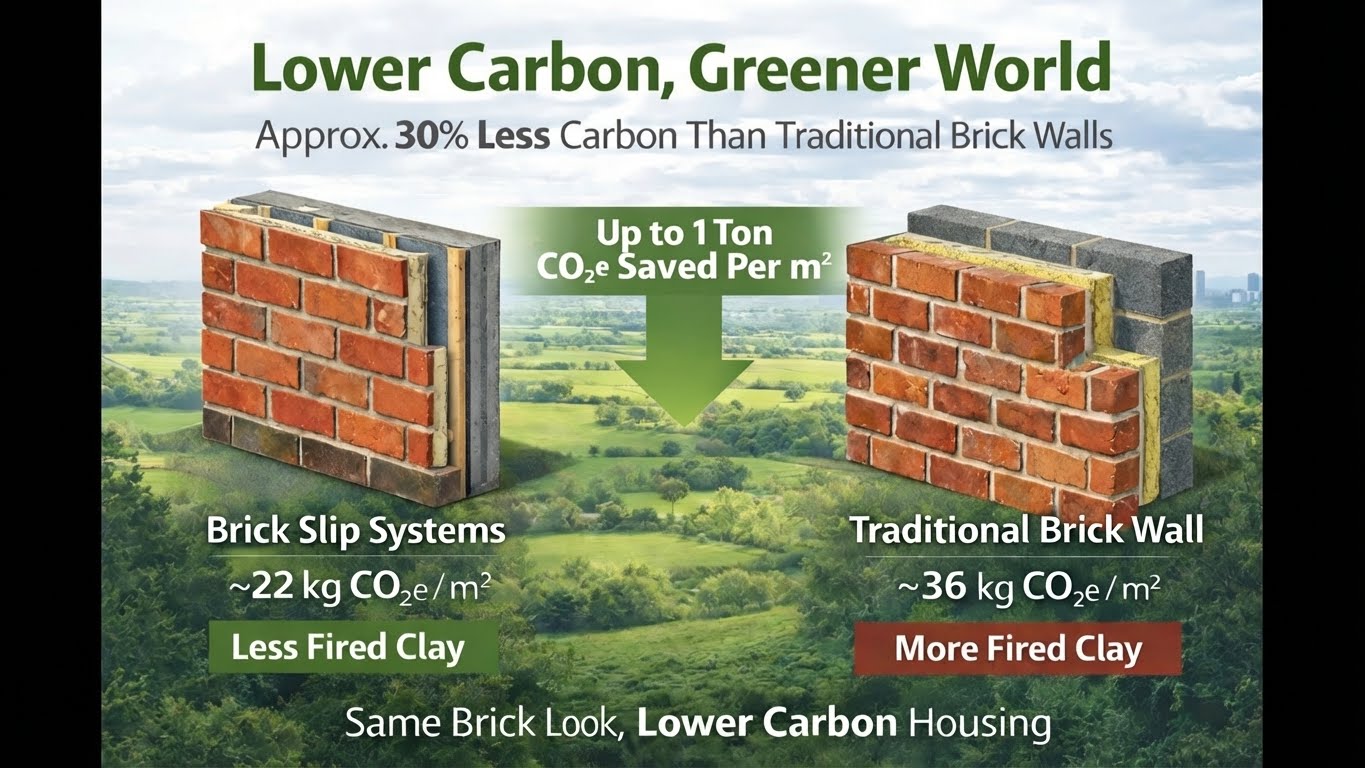

- We use 30% less carbon by comparison to traditional red brick construction (*see our article below).

- Reduce build time by up to 40% and cost by up to 35% compared to traditional red brick builds

- Volume based pricing starting from £30.

Manufacturing Precision Brick Slip Systems

Full compliance solution for internal and external cladding.

We produce A1 non-combustible tracker boards (with or without insulation) engineered for safety, load distribution and durability.

Ideal for tender requirements, high-rise projects up to 18 metres and strict fire regulation zones.

Manufactured for perfectly aligned brick slip installation.

Our EPS (insulation) tracker panels ensure consistent coursing, clean lines and faster installation on every project.

Available in 1200mm x2400mm,40-200mm thickness, with thermal conductivity rating options of 0.038-0.030 W/mK .

Delivering reliable supply through streamlined UK in-house mass manufacturing, we provide high-quality systems at competitive prices.

Consistent stock, predictable lead times and bulk discounts for real saving contractor-focused value.

We work every day to deliver reliable, cost-effective brick slip systems for our partners and clients.

Our production team manufacture A1-rated tracker boards with consistent accuracy, fast lead times and dependable quality. We focus on reducing installation time, improving safety and supporting contractors with quality systems that perform on every build.

The Benefits

Brick Slip Installation Resources

Get practical guidance, expert insights, and real-world tips to help you deliver faster, safer, and more cost-effective brick slip installations.

Questions?

Speak with our team