Helping to transform the face of British construction

Warwickshire-based manufacturer Brick Slip Systems is helping to transform the face of British construction as the country races to deliver 1.5 million new homes in the next five years.

With labour shortages, rising costs, and the growing shift toward Modern Methods of Construction (MMC), the company’s innovative cladding solutions are redefining how — and how fast — Britain builds.

For centuries, bricklaying has been the backbone of British architecture.

But with mounting demand and fewer skilled tradespeople, developers are turning to off-site, panelised, and modular building systems to keep projects on schedule.

This is where Brick Slip Systems is leading the way.

Its A1 fire-rated fibre cement tracker boards and EPS insulated façade panels replicate the appearance of traditional brickwork while delivering the speed, consistency, and efficiency demanded by modern construction.

The company’s cladding systems can be installed up to five times faster than traditional masonry — without the need for bricklayers — making them perfectly suited for off-site assembly lines and on-site modular installations.

From Traditional Brickwork to Modern Methods

The rapid rise of modular and timber-frame housing in the UK has created huge demand for lightweight, adaptable façade systems that integrate seamlessly into factory-built wall panels.

“Our products have been designed from the ground up for modular and timber-frame construction,” explains a Brick Slip Systems spokesperson.

“They allow manufacturers to maintain a traditional brick aesthetic without slowing down production. Homes can be finished in days, not weeks.”

Each panel is lightweight, precision-cut, and factory-ready – designed to fix directly to almost any substrate.

Once affixed the pre-milled panel is ready for slips to be set — consistent in quality and quick to install, even in challenging weather conditions.

What distinguishes Brick Slip Systems is our ability to blend modern performance with timeless style.

Through partnerships with some of the biggest names in the brick slip industry, the company offers a full range of finishes, from contemporary linear profiles to heritage-style handmade bricks.

This gives architects and developers freedom to achieve any look — whether a modern modular apartment block or a traditional family housing development — all while meeting the speed and efficiency targets of MMC.

“Our partnerships allow us to cater to both modern and traditional aesthetics,” the spokesperson adds.

“Developers no longer have to choose between speed and authenticity — they can have both.”

Meeting the UK Housing Challenge

To reach government housing targets, the UK must adopt scalable, sustainable, and high-performance solutions.

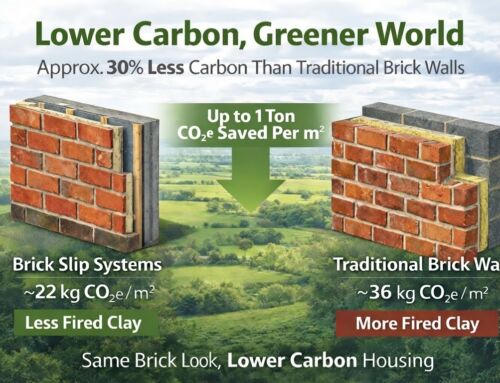

Brick Slip Systems’ products tick every box — reducing site labour, cutting carbon, and delivering precision-engineered façades at scale.

Each panel covers almost 3 m², drastically reducing installation time and costs.

The systems are compatible with timber frame, modular, steel, and concrete structures, offering unmatched flexibility for developers and manufacturers nationwide.

Manufactured in Warwickshire, the company produces over 12,000 m² of façade boards each month, ensuring consistent UK supply and dependable lead times — a crucial advantage in today’s supply chain climate.

Sustainability sits at the core of Brick Slip Systems’ approach.

By producing locally, the company reduces transportation emissions and supports the domestic construction supply chain.

Its fibre cement tracker boards (optional insulation) and EPS insulation panels (40–200 mm) are designed to enhance thermal U values performance while maintaining affordability — with systems starting from around £30.

These solutions are helping housing developers, contractors, and modular manufacturers meet the government’s MMC and net-zero goals, while preserving the architectural heritage of brick-built Britain.

As the UK construction industry evolves, Brick Slip Systems is proving that innovation doesn’t mean abandoning tradition.

By combining authentic brick aesthetics with modern off-site manufacturing techniques, the company is redefining what’s possible in contemporary housing.

Fast. Affordable. Sustainable. Perfect for modular and timber-frame builds.

Brick Slip Systems — Building the Future of UK Construction.