Brick Slip Façade Systems

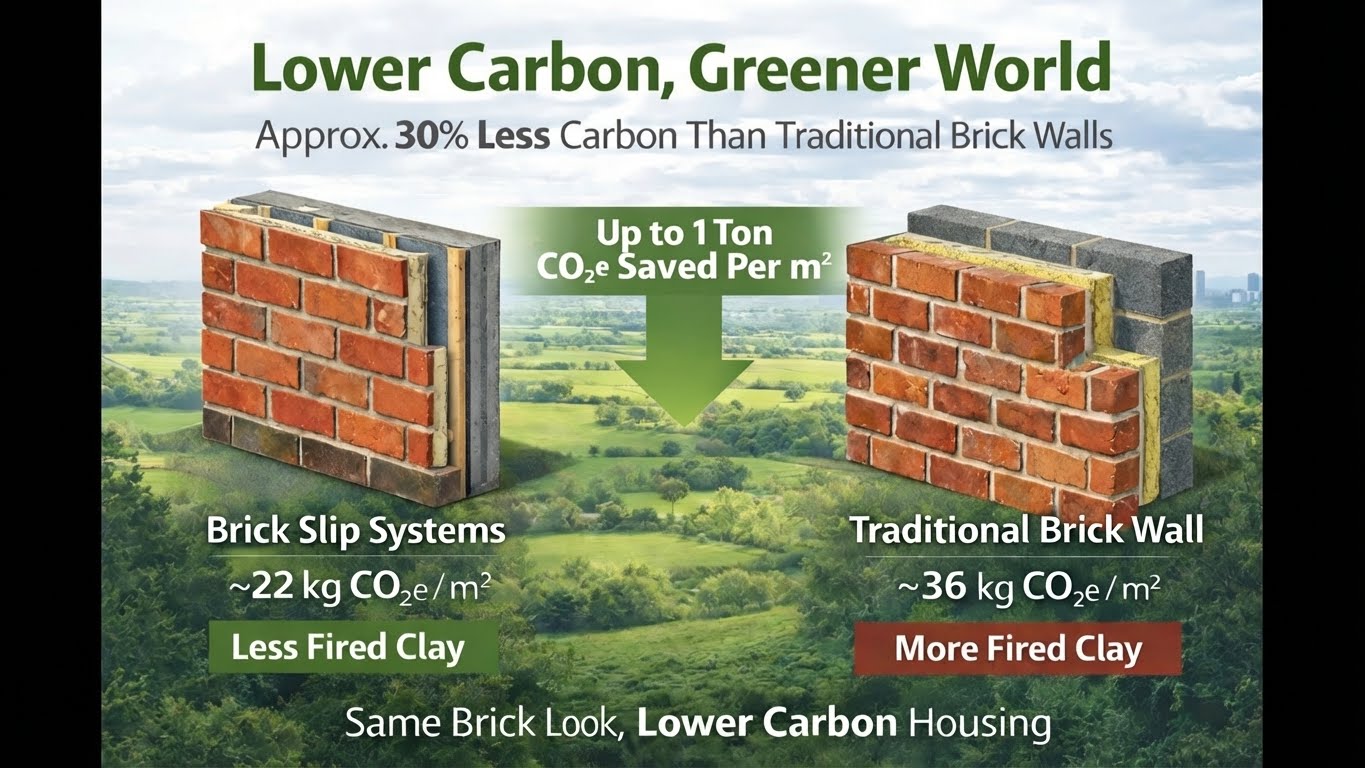

At Brick Slip Systems we understand the importance of both aestheic and practicality: delivering façade systems with the beauty of real brick while meeting the rigorous, evolving demands of modern methods of construction (MMC). Our systems provide real solutions to these challenges and use 30% less carbon by comparisson to traditional red brick construction (*see our article below).

Designed for speed, efficiency and reduced weight our systems provide architects, contractors and developers with a durable, compliant and visually striking façade solution at a fraction of the cost of metal rail support system.

Suitable for new-build and retrofit projects, they deliver faster installation, lower waste and long-term reliability.

Complete System Solutions

Choose from a range of precision engineered façade systems designed for various building types — including fibre cement and EPS carrier panels, insulation options, and mechanical support components. Each system ensures consistent brick alignment, secure fixing, improved thermal performance and streamlined on-site installation.

Wide Range of Brick Slip Finishes

Select from our extensive catalogue of real clay and mineral brick slips, including traditional reds, multis, buffs, greys and contemporary tones. All options are manufactured to meet façade requirements, offering the same texture, colour variation and detailing as traditional brickwork.

WHY CHOOSE BRICK SLIP SYSTEMS?

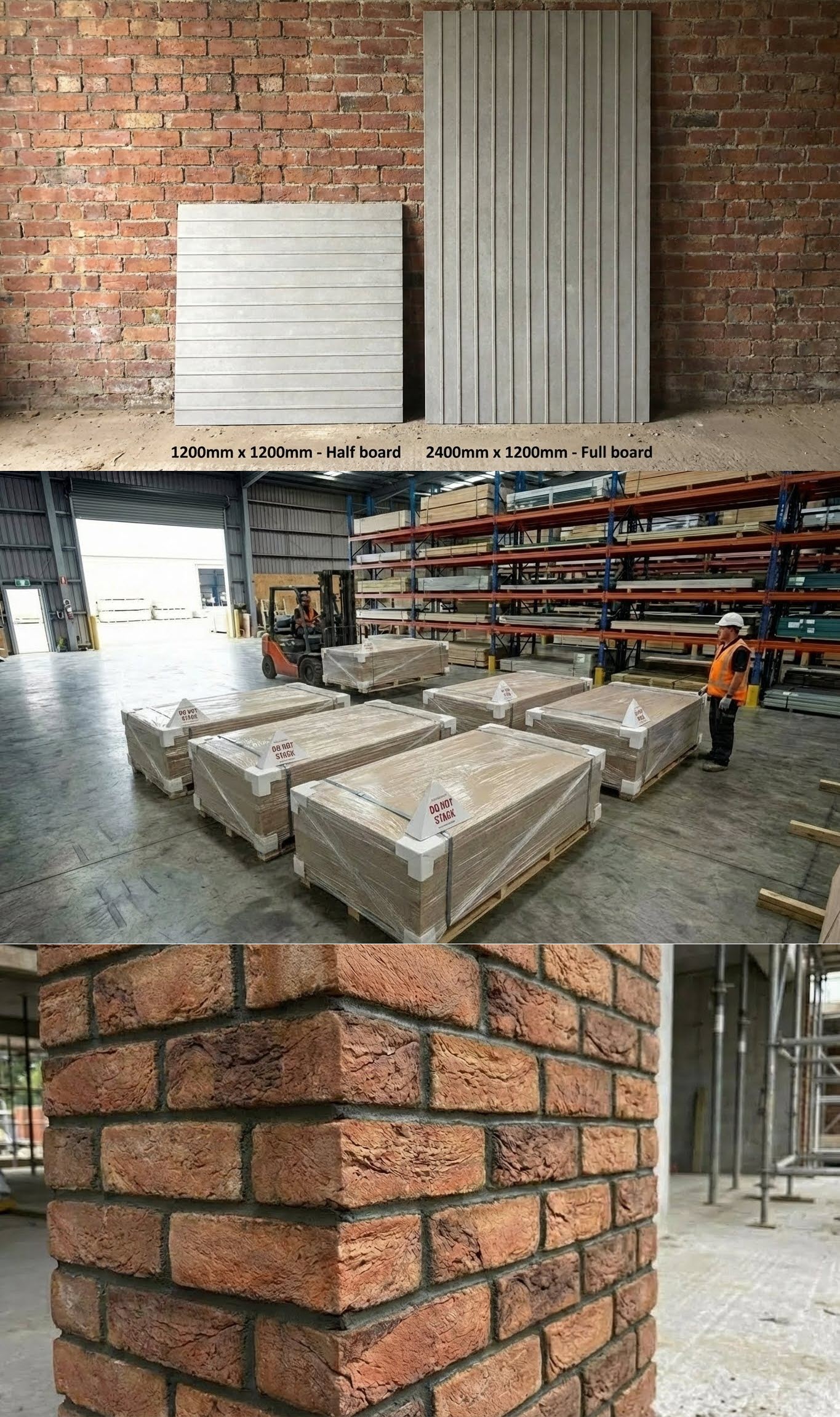

Our fibre cement has ideal properties as a cladding material – resistant to rot, warping, impact, pests, and UV rays. It is water-resistant and has excellent thermal and noise insulation properties. Depending on your chosen brick (typically 40-75mm), we precisely mill the brick tracks to size, with 1mm tolerance on either size and a 3mm deep groove for slip retention. Our boards are supplied with insulation if required and are easy to cut, pilot and affix to building exteriors.

Our large format flexible panel sizes means buildings can be clad quickly by comparison to typical market offerings and we deliver significantly better coverage-to-cost ratio. An average competitor charges £60/m2, our boards are 2.88 m2 and start from £30, offering exceptional comparative value per installed square metre.

*Volume-based pricing available – ask us for our costing sheet

Two Systems combine for one complete façade solution

Fibre-Cement Brick-Slip Tracker Boards

Specifications

- Large format: 2440 × 1200 mm (cut to any size, halves, quarters, bespoke)

- 2.88 m² coverage per board 12mm thick, with a 3mm groove for retention and 10mm mortar joint.

- Tailored to bespoke brick sizes ranging between 38-75mm (2mm tolerance)

- Tailored to any brick type: Linear, metric, reclaimed etc

- Supplied with or without insulation Thickness options: 20 mm – 200mm *Fire-Resistant & Fireproof insulation variants available on request

- EPS+ Insulation provides Thermal conductivity between 0.030 W/mK and 0.038 W/mK (dependent on grade requested).

- 200 Grade – High density EPS Compressive strength – 200kPa @10% strain BS EN 13163

- Tensile Strength – minimum 100kPa BS EN 1607

- *Also available as plain render board

Key Advantages

- A1 non-combustible

- Pre-grooved tracker lines for fast, level installation

- Easily cut and piloted

- Suitable for timber frame, steel, masonry, concrete & modular

- Indistinguishable from traditionally laid brickwork

- Over 4000+ produced per month

- Prices from £30

EPS Milled Insulation Panels

A fully insulated cladding system made from precision-milled expanded polystyrene (EPS).Designed as a direct brick-slip carrier or as an insulated backing board bonded to our fibre-cement tracker panels.

Specifications

-

Large format: 2440 × 1200 mm (cut to any size, half, quarters) 2.88 m² coverage per board.

-

Thickness options: 20 mm – 200mm.

-

Material: High-density, EPS+ custom-milled to order.

-

Compatibility: Breeze block, timber frame, concrete, modular, steel, and masonry structures.

-

EPS HP+70 E (grey) as defined in BS EN 13163, contain a flame retardant additive to achieve Reaction to Fire Class E (Fire Retardant Grade) However *Euroclass B-s1, d0: Achievable when EPS is used within an External Wall Insulation (EWI) system that is fully encapsulated by non-combustible layers like render.

-

EPS awarded an A+ rating by the BRE’s Green Guide to specification.

-

Boards are BBA certified.

-

*Also available as plain insulation board in various grades.

Key Advantages

-

Provides insulation and slip support in one lightweight system for projects.

-

*Can be supplied with fibre cement rear mounting board to provide full encapsulation if cavity for increased resistance to fire *Euroclass B-s1, d0

-

Ideal for both retrofit and new-build

-

Factory-milled in the UK for short lead times

-

Reduces thermal bridging and boosts building thermal performance ratings

-

Installed without fibre-cement board

-

Prices from £30

The Process

Our brick slip façade systems are designed to streamline installation while ensuring a high-quality, authentic brick finish. Each system combines precision-manufactured slips with engineered carrier panels to deliver consistent performance across all project types — from modular builds to large-scale developments.

Step 1 — Prepare the Building Envelope

Ensure the structural wall or framework is ready to receive the façade system. Depending on the build, this may involve installing insulation, breather membranes and system-specific rails and brackets.

Our façade systems can be fixed to masonry, timber frame, concrete, steel frame and modular structures, providing flexibility across multiple project types.

Step 2 — Install the Façade System Panels

Engineered carrier panels are fixed securely to the buildings substrate using battens every 400mm. These ensure consistent weight distribution, allow a ventilated cavity to prevent damp and ensure a stable base for brick slip application.

Once installed, brick slips are secured to the system using either mortar or adhesive depending on the specification.

Step 3 — Point & Finish

After the slips are affixed, the joints are pointed using the appropriate colour matched exterior-grade mortar to create a strong, weather-resistant and visually seamless brick façade.

The result is a finished surface that replicates the look of traditional brickwork while offering enhanced speed, reduced weight and long-term durability.